Master Production Planning & Control – Build Efficiency from Day One

Unlock the secrets of modern production strategy. Learn how to develop accurate production schedules, optimise resources, and respond to real-time demand with agile and efficient planning.

This course equips you with practical tools and techniques to improve productivity, reduce waste, and ensure timely deliveries — all through a flexible online format.

Find out everything about Demand Forecasting, Planning Tools and Techniques, Inventory Management and Control, Production Scheduling and Sequencing, Real-Time Production Control, Capacity Planning and much more!

Target audience:

Managers, Planners, Production responsibles, Distribution responsibles, Operations, Supply Chain, Purchasing, Stock, Planning and Logistics Managers and other recipients who wish to specialize in this subject or start a related professional career.

General Objective:

1. Prepare students to perform production planning and control functions in different industrial sectors;

2. Provide the methodologies and tools needed to optimize processes, reduce costs and improve production efficiency;

3. Provide a solid foundation for managing resources, stocks, production capacity and performance indicators;

4. Develop skills in the use of digital tools and software to support planning.

Certificate

Upon successful completion of your course, you will receive the Learnisia International Courses Certificate — an official recognition of your dedication, effort, and newly acquired skills.

Our certificate is issued in digital format, includes authenticity verification, and is valid for presentation in any country, serving as proof of your continuous training or professional specialization.

Whether you're strengthening your CV, applying for new opportunities, or seeking international recognition of your qualifications, the Learnisia certificate is the credential that highlights your learning journey.

Invest in yourself. Believe in your potential. Get certified with Learnisia.

Training Team

Meet Your Instructor

Your instructor for the Production Planning and Control course is a Senior Training Manager with a university degree in Computer Science and Management, and over 25 years of hands-on experience in business management and industrial production.

Throughout his career, he has led teams, optimized production processes, and implemented strategic planning systems across various industries.

His extensive expertise ensures that every concept in this course is rooted in real-world application — combining academic knowledge with years of practical insight.

Learn from experience. Be guided by excellence.

Specific Objectives

1. Understand the concept of production planning and control (PPC) in the industrial context;

2. Identify the different types of production systems and their characteristics;

3. Recognize the strategic importance of PPC for business competitiveness;

4. Know and apply different production planning techniques;

5. Construct schedules and Gantt charts;

6. Develop short, medium and long-term plans;

7. Understand the importance of stock and resource management for planning;

8. Learn to classify and manage different types of inventory;

9. Apply stock control and rotation techniques;

10. Determine the production capacity of a line or set of machines;

11. Perform efficient sequencing of production orders;

12. Understand capacity constraints and mitigation strategies;

13. Define key performance indicators (KPIs) for production monitoring;

14. Implement control and continuous improvement systems;

15. Use performance analysis methods and tools (PDCA, Six Sigma);

16. Simulate real production planning and control situations;

17. Know specialized production planning and management software.

A Course designed for Real-World Application – Learn by Doing

From theory to practice – bridge the gap with real scenarios. Through simulations, case studies, and expert insights, you'll gain actionable skills that reflect real industry challenges. Whether you're new to the field or seeking to upgrade your expertise, this course gives you the confidence to take control of production flows and meet company goals.

Course Outline

1. Initial Concepts of Production Planning and Control

- Definition of PPC and its historical evolution;

- Relationship between planning, programming and control;

- Main activities and responsibilities of a planner.

2. Types of Production Systems

- Mass production, series production, production to order and continuous production;

- Classifications of production processes (job-shop, flow-shop, projects, batches);

- Advantages and disadvantages of each system.

3. Production Strategy

- Role of planning and control in the operations strategy;

- Alignment with the organization's competitive strategy (costs, flexibility, quality, delivery time).

4. Material Flow and Production Layouts

- Material and information flow;

- Types of layout: functional, by product, in cell and hybrid;

- Analysis of advantages and disadvantages and impact on PPC.

5. Relationship with Other Departments

- Interface with purchasing, logistics, maintenance, engineering, quality and marketing/sales;

- Importance of internal communication for successful planning.

1. Production Planning Techniques

- MRP (Material Requirements Planning);

- MRP II (Manufacturing Resource Planning);

- ERP (Enterprise Resource Planning)

2. Aggregate Planning

- Concepts and importance of aggregate planning;

- Aggregate planning strategies (variable labor, inventories, subcontracting, etc.);

- Resource sizing models and exercises.

3. Master Production Schedule (MPS)

- Preparation of the MPS;

- Link between MPS and aggregate planning;

- Practical applications.

4. Detailed Scheduling

- Gantt charts: interpretation and construction;

- Scheduling: concepts of lead time, setup time, order priority;

- Sequencing techniques (FIFO, LIFO, SPT, EDD, etc.).

5. Balancing of Production Lines

- Objectives of line balancing;

- Balancing methods (heuristics and mathematics);

- Balancing efficiency indicators.

1. Material Resource Management

- Definition of direct and indirect resources;

- Resource allocation and availability restrictions;

- Conflicts in resource use and prioritization of production orders.

2. Stock and Inventory Management

- Types of stocks (raw materials, semi-finished products, finished products, maintenance);

- Inventory classification methods (ABC, XYZ);

- Cost of ownership, ordering costs, cost of rupture and total stock cost.

3. Stock Management Models

- EOQ (Economic Order Quantity);

- Economic production batch;

- Safety stock management model;

- Just in Time (JIT);

- Kanban.

4. Demand Forecasting

- Time series and forecasting techniques (moving average, exponential smoothing, regression);

- Forecast error and evaluation methods (MAD, MSE, MAPE);

- Importance of sales forecasting for stock planning.

1. Capacity Planning

- Concepts of nominal, effective and real capacity;

- Factors that affect capacity (maintenance, setup time, absences, etc.);

- Long, medium and short-term capacity planning.

2. Theory of Constraints (TOC)

- Identification of bottlenecks;

- Methods to eliminate or minimize the impact of constraints;

- Practical application in production lines.

3. Sequencing

- Order prioritization criteria (FIFO, LPT, SPT, EDD, etc.);

- Dispatching rules;

- Reduction of setup times (SMED – Single Minute Exchange of Die).

4. Optimization Models and Methods

- Introduction to optimization methods in planning (linear, integer, heuristics);

- Computational tools for solving sequencing problems.

1. Key Performance Indicators (KPIs)

- Definition of relevant KPIs for planning (OTD, OEE, OTIF, average lead time);

- How to select and measure indicators appropriate to the business;

- Interpretation of results and decision-making.

2. Production Control Systems

- Control of production orders (Shop Floor Control);

- Data collection methods (manual, automatic, IoT);

- Integration with ERP and MES (Manufacturing Execution System) systems.

3. Continuous Improvement Cycles

- PDCA Cycle (Plan, Do, Check, Act);

- Application of Lean and Six Sigma tools (DMAIC);

- Identification of waste and opportunities for improvement.

4. Reports and Dashboards

- Preparation of performance reports;

- Creation of dashboards with indicators;

- Communication of results and action plans.

1. Integrated Case Studies

- Construction of an aggregated and detailed plan in a fictitious case;

- Application of sequencing and capacity management techniques;

- Stock calibration and analysis of performance KPIs.

2. Digital Planning Support Tools

- ERP and PPC modules (SAP, Oracle, Microsoft Dynamics, etc.);

- Specialized scheduling and optimization software (Preactor, Arena, etc.);

- Collaborative planning tools (Trello, Monday, etc.).

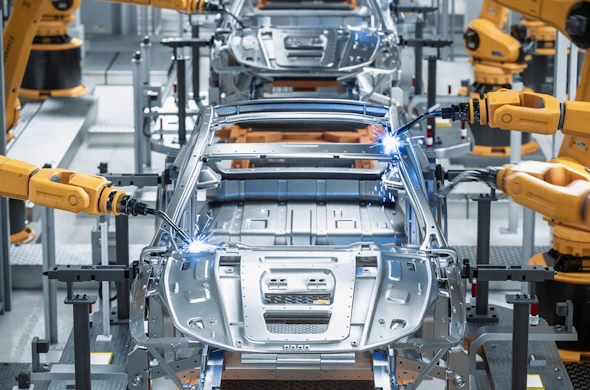

3. Integration with Industry 4.0

- Concepts of Industry 4.0 and Smart Factories;

- IoT, Big Data and cyber-physical systems in production planning;

- Examples of implementation of advanced technologies in factories.

100% Online, Globally Recognised Certification

Study at your own pace, from anywhere in the world. This certified e-learning program allows you to manage your study schedule flexibly, without disrupting your routine. Upon completion, you’ll receive a Learnisia International Certificate – recognised across borders, opening doors to new career opportunities in manufacturing and supply chain management.